19.11.2025

Ivan Landa

The lintel above the window is one of the riskiest places in the entire building envelope. It is a detail that meets high demands on statics, thermal insulation and the correct installation of external shading. If you make a mistake here, it will affect comfort, energy bills and the lifespan of the facade. In this article, we will therefore look at how the problem of a “critical” lintel can be solved using purenit, what exactly a lintel box made of purenit does and when it is worth choosing a system solution from a specialized manufacturer.

What is a lintel above the window and why is there a problem with thermal insulation?

The lintel above the window is a load-bearing building element that transfers the load of the masonry above the window opening. Reinforced concrete or ceramic lintel are most often used. Although these materials are statically advantageous, they have significantly worse thermal insulation properties.

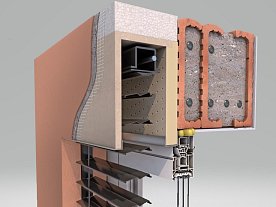

The space above the window is also very limited. Outdoor blinds or screen shutters are often planned in this zone, which is why there is not much space left for high-quality insulation. Concrete has high thermal conductivity and the lintel thus creates a significant thermal bridge. This can cause local cooling, condensation and subsequently mold.

Another problem is the accumulation of technical requirements, because the window connection joint, the shielding box, the electrical installation and the anchoring must all fit into one place. This area is therefore one of the most complicated parts of the entire facade.

And this is where purenit and prefabricated lintel boxes come in, a system that combines load-bearing structural material and high-quality thermal insulation in one building element.

What is purenit and why is it ideal for use above windows?

Purenit is a PUR/PIR-based structural material that combines high strength, low thermal conductivity and very good resistance to moisture and aging. It has the character of a solid structural board, but at the same time it acts as an excellent thermal insulator. Typical values of thermal conductivity of purenit are around 0.07-0.08 W/m·K, which is several times better than concrete.

The material has high dimensional stability, does not work with changes in temperature and humidity and does not absorb. Thanks to this, it maintains its properties in the structure for a long time, even in places with higher humidity or in direct contact with plaster.

How does purenit work in practice?

At ISOparts, we use purenit precisely where there is a common problem with the quality of workmanship and where it is necessary to combine static and thermal insulation requirements. The material is resistant to moisture, construction chemicals and mechanical stress. At the same time, it is easy to machine, it can be cut, milled, drilled or screwed like wood.

Purenit is also extremely strong in compression, which is why it is used as a base material for heavy window systems and as a construction board for loading boxes. In the area above the window, it not only solves thermal insulation, but also the load-bearing capacity for anchoring blinds.

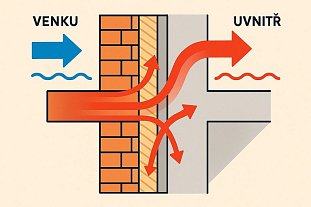

Why is the lintel above the window a thermal bridge and how can purenit solve this problem?

In classic transom systems, a thermal bridge occurs mainly due to the massive reinforced concrete. This part of the facade has low thermal resistance and cools down faster than the surrounding structure. However, there is also limited space above the window for additional insulation, especially if shading technology is installed.

Purenit helps to solve this problem in two ways. On the one hand, it wraps or replaces the cold parts of the detail with a material with low thermal conductivity. On the other hand, it creates a structural foundation into which blinds can be safely anchored without having to cut through the insulation to the concrete.

This leads to a significant reduction in the temperature gradient in the lintel area and to the elimination of the risk of condensation and mold. In practice, this improves thermal comfort in the interior, while increasing the service life of the entire window detail.

What is a lintel purenit box and how does it work above windows?

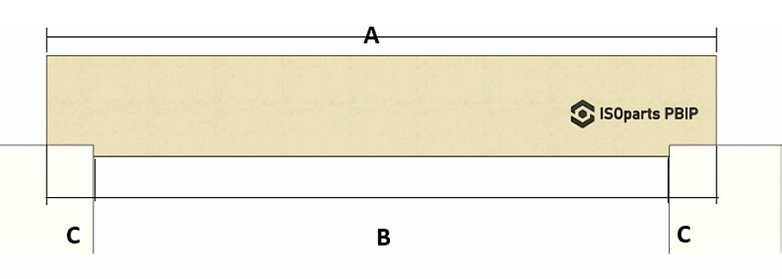

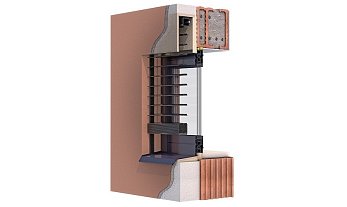

At ISOparts, we produce Purenit lintel boxes = prefabricated elements intended directly for the lintel zone. This box combines a Purenit construction board, PIR insulation and an assembly profile, thanks to which it replaces several construction procedures at once.

The front, top and side walls of the box are made of Purenit board, which ensures strength and the possibility of safe anchoring of blinds. The back side is made of PIR insulation, which adjoins the lintel and ensures a significant reduction in thermal bridges. The assembly U profile then allows for precise connection of the box to the window frame.

What are the advantages of a Purenit lintel box compared to "assembling from materials on site"?

Using a pre-made box brings high precision and clean execution. Nothing is cut, folded or improvised on site. Installation is fast and repeatable. Thanks to the combination of Purenit and PIR, thermal insulation and the structural function of the detail above the window are solved at the same time.

Another advantage is the possibility of anchoring blinds directly into purenit, which eliminates thermal bridges that occur when anchoring through insulation into concrete. The box is part of the facade after plastering, so the resulting detail is aesthetically clean and technically correct.

What technical advantages does purenit have in lintels above windows compared to classic materials?

Purenit is characterized by very low thermal conductivity, high strength and minimal water absorption. It is around λ ≈ 0.07-0.08 W/m·K, which is a value close to better thermal insulation and significantly lower than that of concrete. It is the combination of these properties that predetermines it for use in the lintel area. While concrete has high thermal conductivity, purenit maintains values similar to high-quality insulation, and can still withstand the mechanical load of blind consoles.

So when you wrap the cold parts of the detail with purenit, or use a lintel box made of purenit and PIR insulation, you significantly reduce the temperature gradient in the lintel area. This prevents a “cold zone” from forming above the window from the inside and the dew point moves closer to the outer face of the structure.

Purenit boards do not serve as a load-bearing lintel (which is still made of reinforced concrete or another static element), but as a structural and insulating supplement. They improve the thermal protection of the detail, but at the same time allow the installation of accessories without disturbing the insulation layer.

The material is also extremely resistant to moisture. In the lintel area, where moisture from condensation or rainwater often occurs, purenit does not swell, does not deform and retains its original shape and strength for a long time.

How is the design and installation of a purenit transom box carried out and when is it worth considering it?

At ISOparts, we recommend using a purenit transom box especially in buildings where outdoor blinds or screen shutters are planned. It is also important in low-energy and passive houses, where minimizing thermal bridges is very important. It is also advantageous to use it in demanding renovations where it is necessary to ensure clean and technically correct detail.

What is the design and installation procedure?

First, a box design is prepared according to the window dimensions and the type of shading. We make the box to measure so that it exactly follows the window frame and allows for the correct anchoring of the blinds.

On site, the box is installed in the lintel area before the insulation system is applied. Installation is simple because most of the details are already prefabricated. It is then connected to the window frame, the connection joint is sealed and the box is integrated into the insulation system. After plastering, it acts as a clean part of the facade. After the facade is completed, blinds or screens can be installed directly into the purenit without any problems.

What types of Purenit elements above windows do we offer at ISOparts?

At ISOparts, we produce a comprehensive system of elements around windows that allows us to solve the entire detail from the window sill to the lintel. This includes, in particular, Purenit flush-mounted boxes for blinds and screen shutters in various types. These boxes can be straight, corner, custom-made or modified for atypical openings.

For the lintel area, we have developed the lintel PurBox, which is specially designed to achieve high thermal insulation parameters and at the same time allows for safe anchoring of the shielding. In addition, we also offer Purenit insulating lining with an integrated housing for guide rails and various mounting pads or cubes made of Purenit.

Thanks to these elements, the entire window detail can be designed as one comprehensive system. The result is a clean design, high quality and minimal risk of installation errors.

So is Purenit in the lintel above windows more advantageous than a regular "under-wall" or a classic lintel?

A classic solution often involves a combination of concrete, OSB boards, EPS insulation and other elements that must be carefully matched. These materials have different properties, work differently and often create thermal bridges or complicate the installation of blinds.

The purenit system offers a unified solution. The lintel detail is thermally and structurally resolved, the prefabricated elements are precise and allow for quick installation. Blinds can thus be safely anchored without interfering with the insulation. The entire system is also long-term stable, moisture-resistant and suitable for passive houses.

Why choose purenit for lintels above windows?

The lintel above a window is a technically demanding place that significantly affects thermal comfort, the lifespan of the facade and the functionality of the external shading. Purenit brings a combination of strength, low thermal conductivity and dimensional stability, making it ideal for this area.

At ISOparts, we combine purenit with PIR insulation and produce prefabricated lintel boxes that solve the detail as a whole. The result is a minimization of thermal bridges, quick installation, a clean facade appearance and secure anchoring of the blinds.

If you are planning new windows, external blinds or a complete renovation, the Purenit solution is a reliable and long-term profitable choice. We will be happy to prepare a solution proposal specifically for your project. Just contact us.